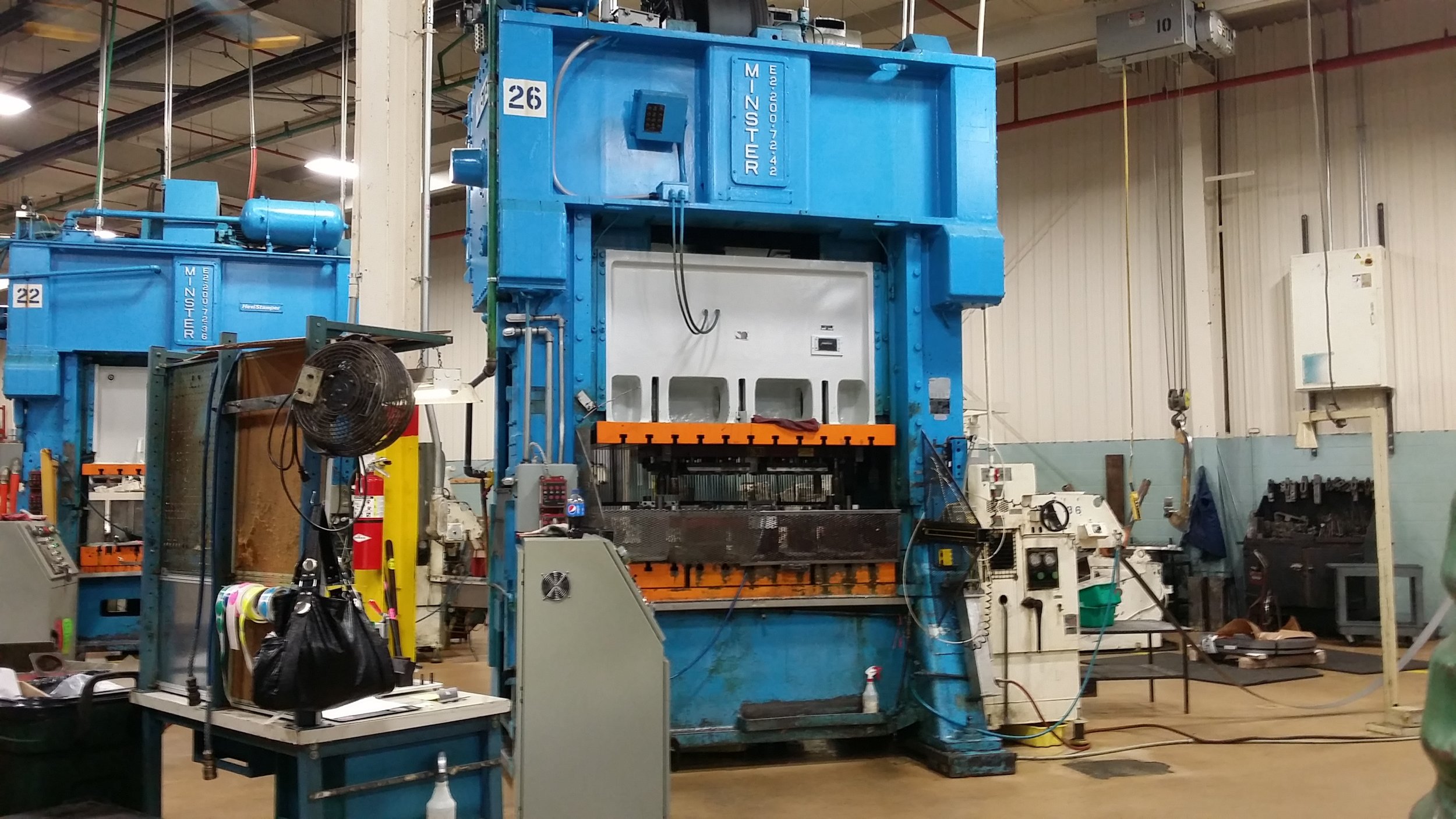

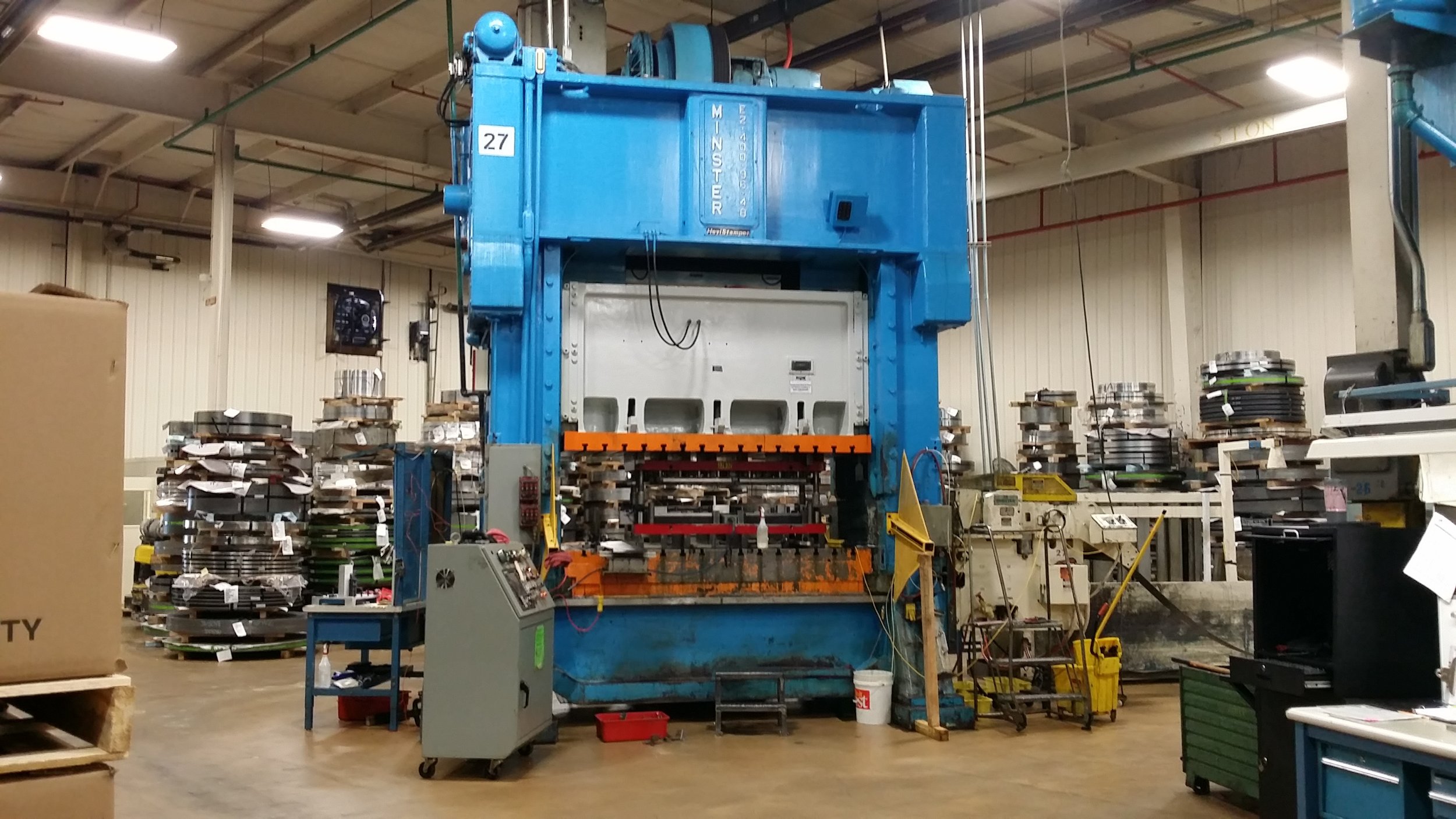

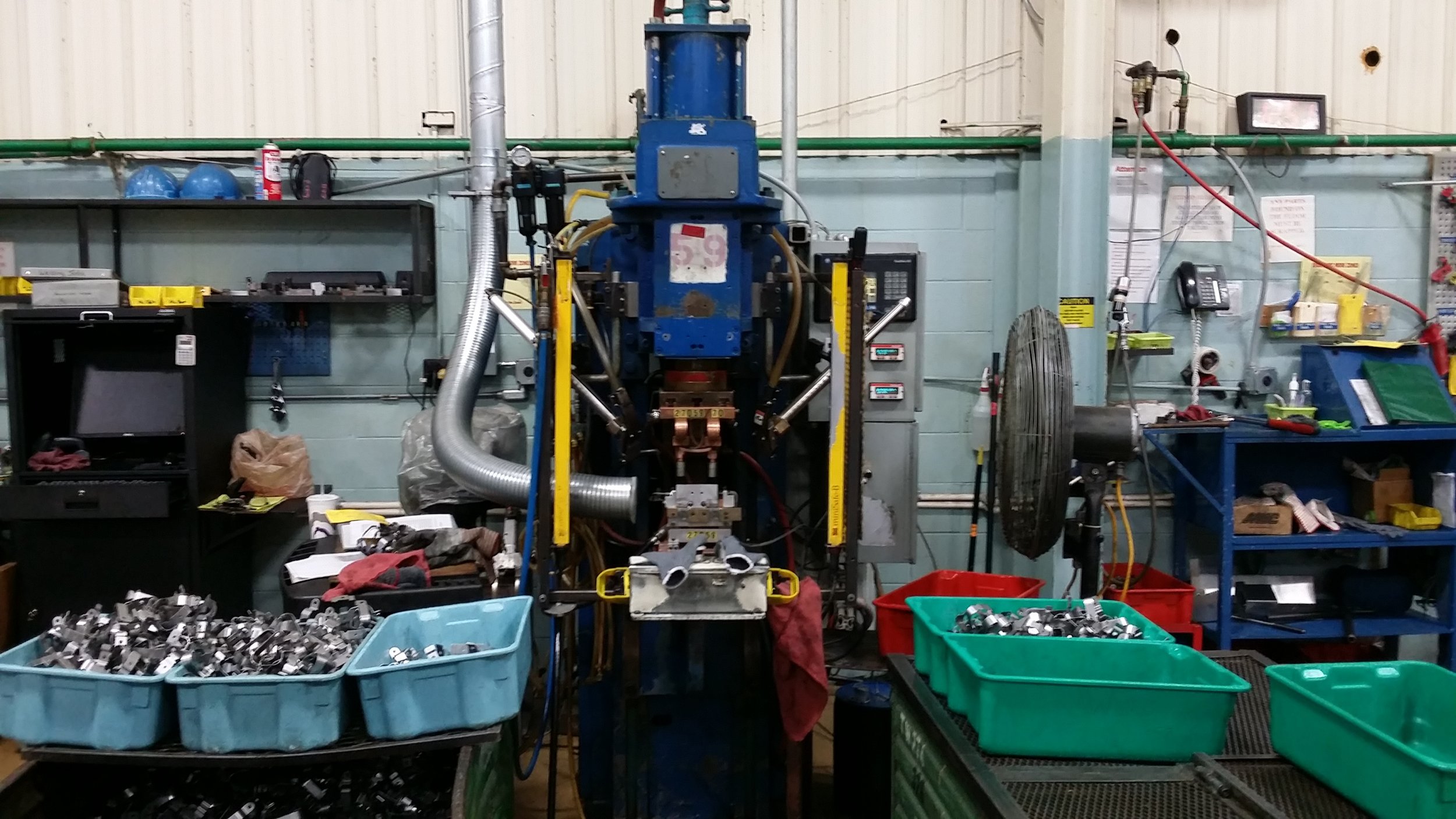

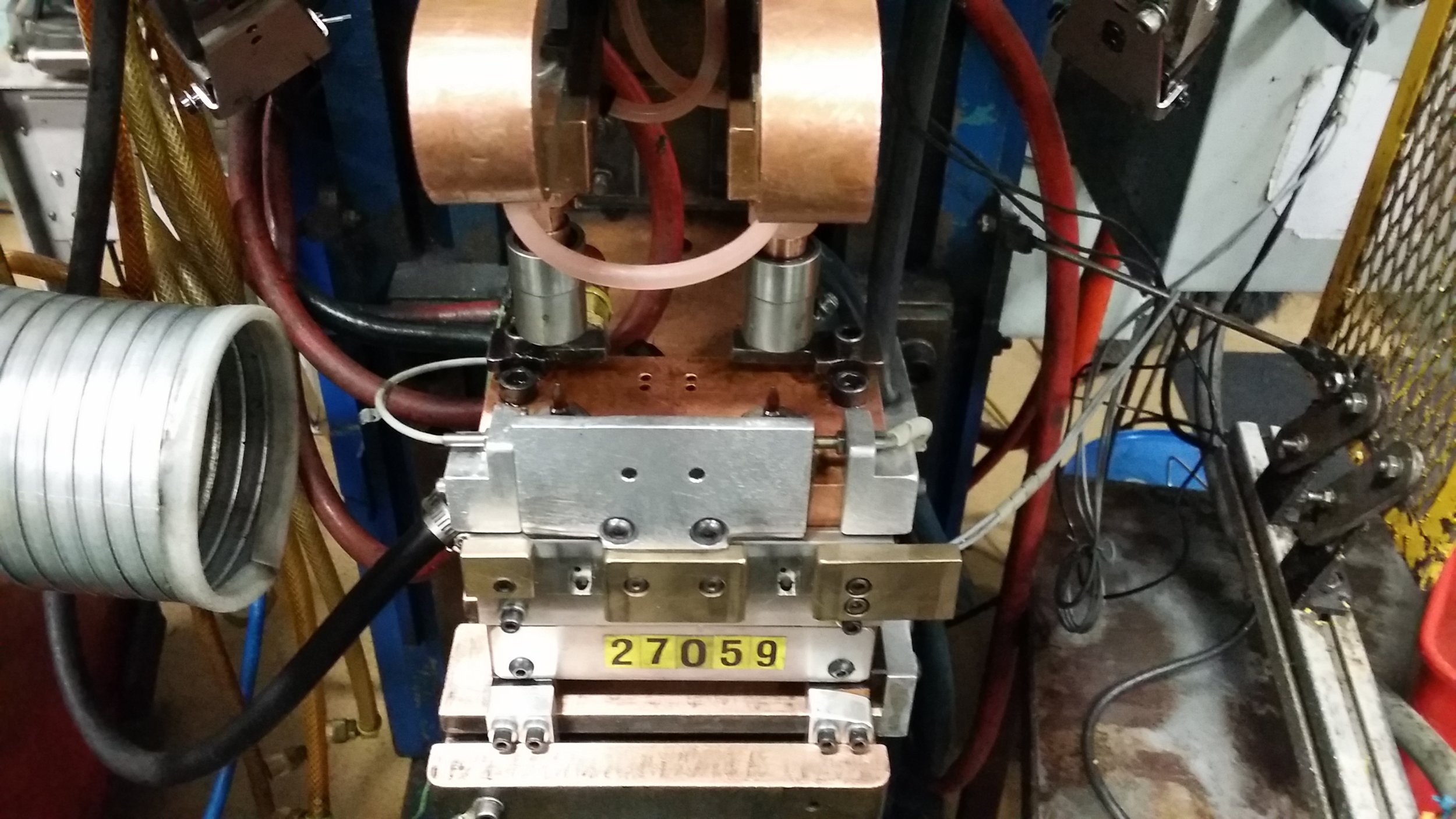

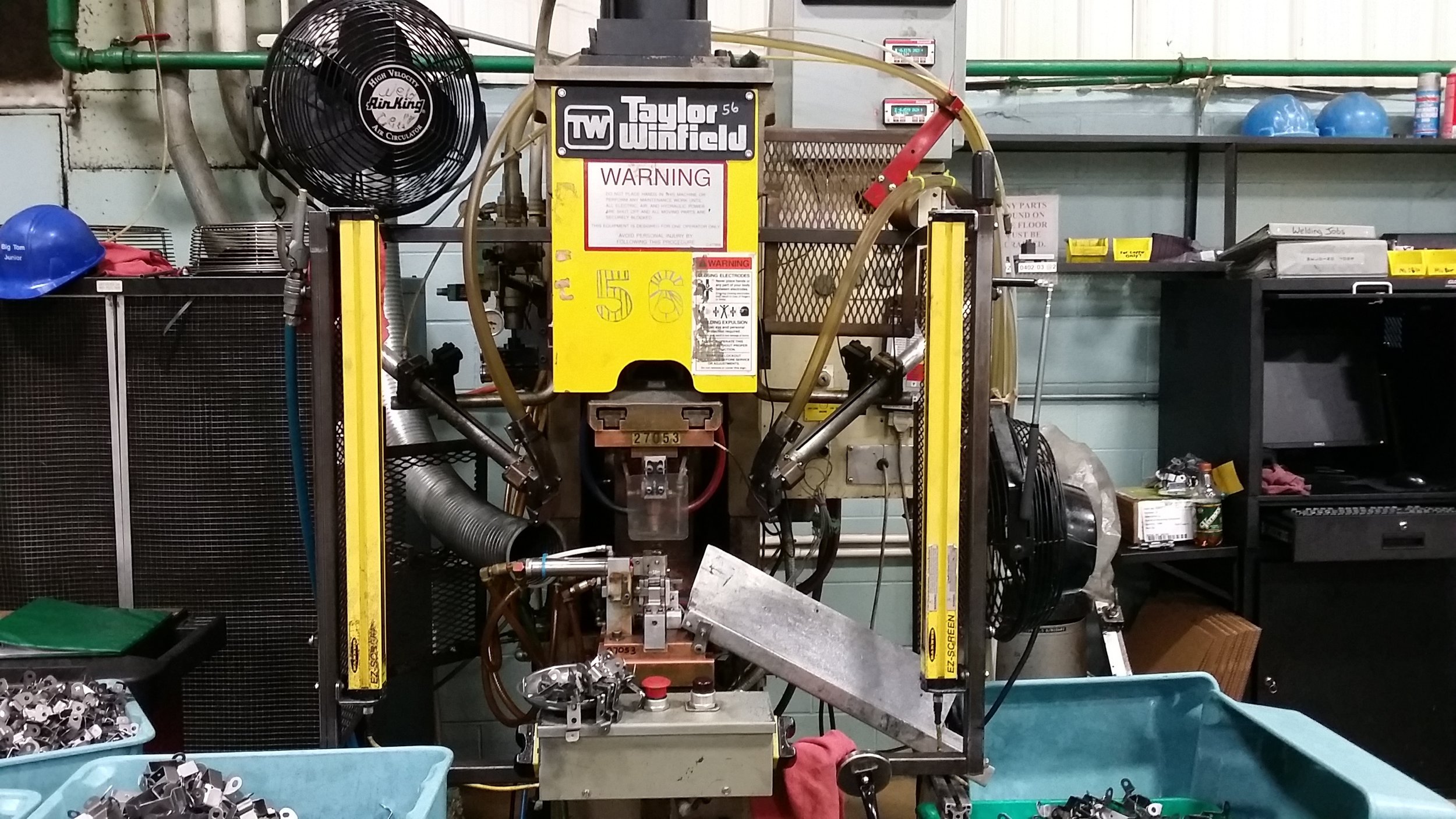

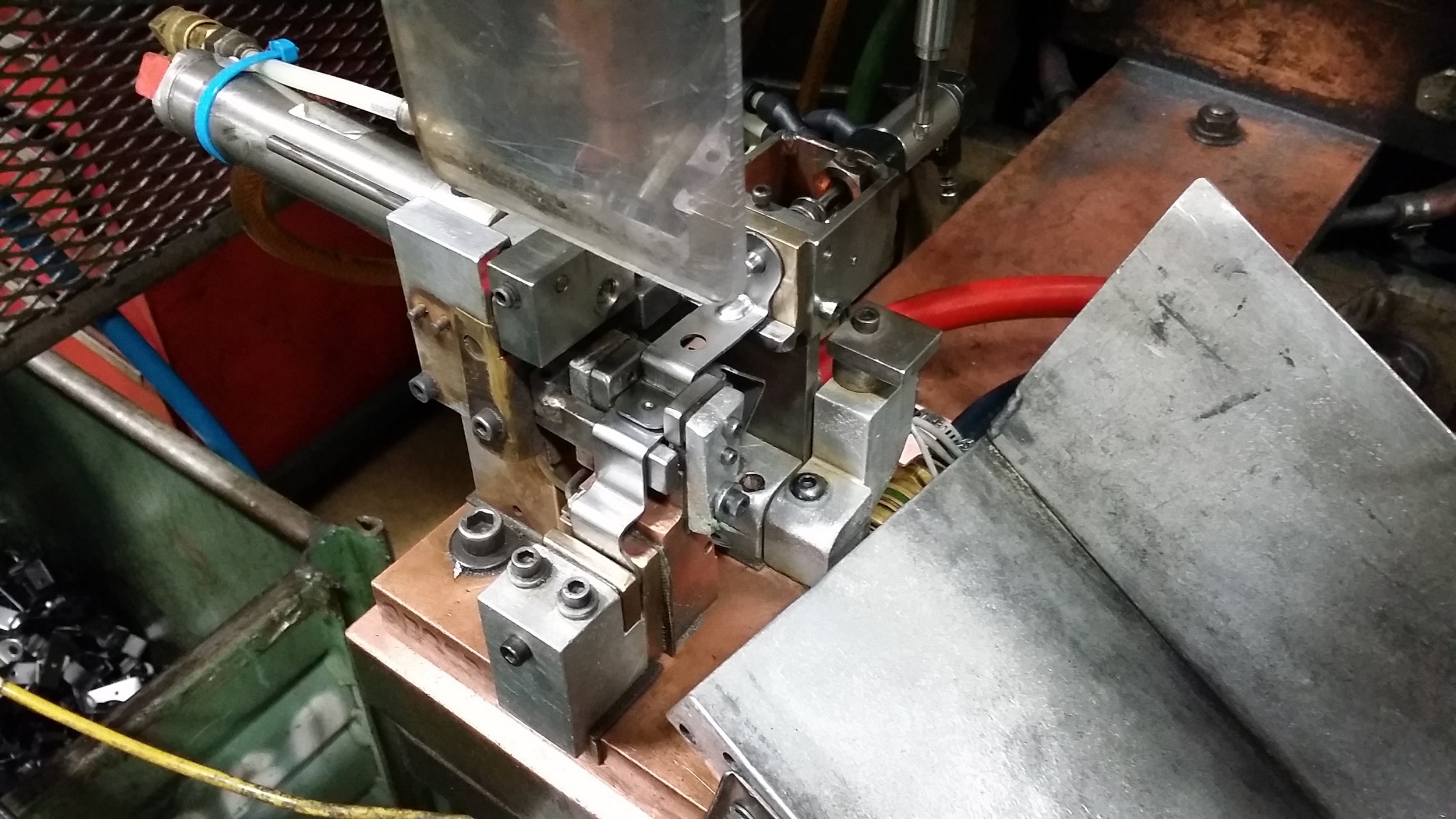

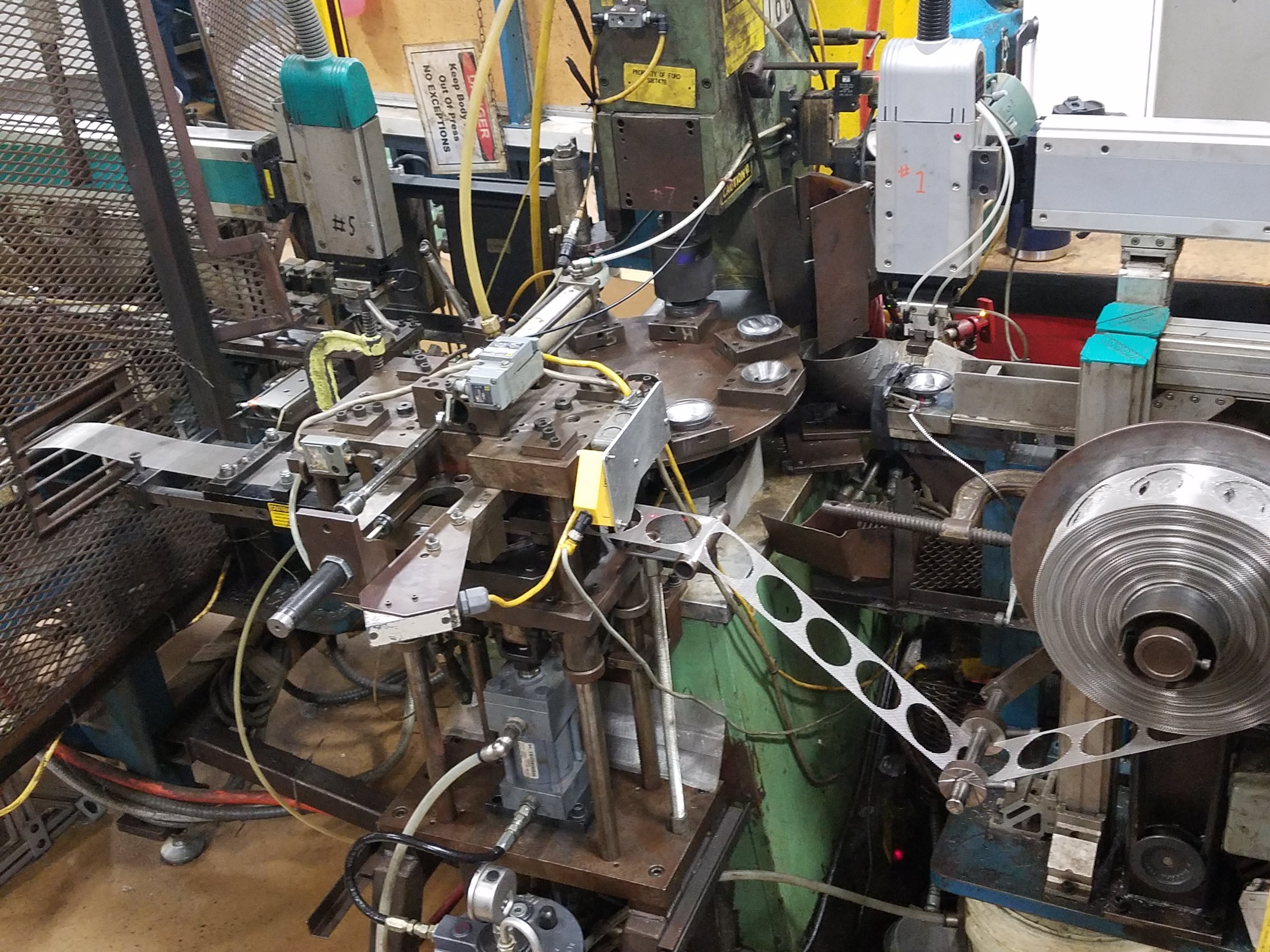

Production & Tryout- Our modern press room has presses ranging from 50 to 600 ton capacity. All of them meet OSHA's safety requirements and many are equipped with light curtains or pullbacks and electronic sensoring. We also have two four-slide production machines and two assembly machines to further enhance our competitive production edge. Six in-house production welders allow us to weld nuts, studs and mating components to provide our customers with a total one stop production service. Our floors are sealed and are scrubbed daily with clearly labeled areas for all production items, tooling and maintenance equipment.

Finishing and Packing- At DieTech, we maintain our own finishing department to tumble, vibratory deburr, wash and rustproof our product to insure the customer's satisfaction upon receiving their goods. Bar code labeling insures accurate counts and descriptions of all products produced.

Transport- Getting customers what they want is not enough, when they want it is just as important! DieTech has two modern Freightliner box trucks and two commercially licensed drivers on staff to ensure prompt on-time delivery or pick up. When circumstances prevent our semi from making required stops we also maintain a fleet of new pick-up trucks and a trailer and even have a stand by account with a local truck rental firm to get a same day rental if necessary.